1.Special attention: The pipeline must be cleaned and blown before installation to avoid impurities blockingthe valve port and damagingthe sealing surface.In case of small impurities and dust, filter should beinstalled before the valve(Filter screen >80mesh).

2.Pay attention that the arrow on the valve body should be in line with the flow direction of the pipe, and thecoil should be installed verticallyupward and horizontally.

3.Before installation, check whether the pressure, temperature, voltage and solenoid valve nameplate andactual parameters are consistent.

4.Payattention to the cleanliness ofthe medium. The valve body parts should be cleaned regularly duringuse, and the gasket should be checked at the same time after disassembly. lfany damage is found,it shouldbe replaced in time.

5.Duringinstallation, use a wrench to clamp the valve bodyand then twist the pipe must not force on the coil.so as not to make the internal bending deformation ofthe solenoid valve and loose joints leading to leakage

6.Solenoid valve installation must be through the fluid action for severaltimes, to ensure that the normaoperation,can be putinto normaluse.

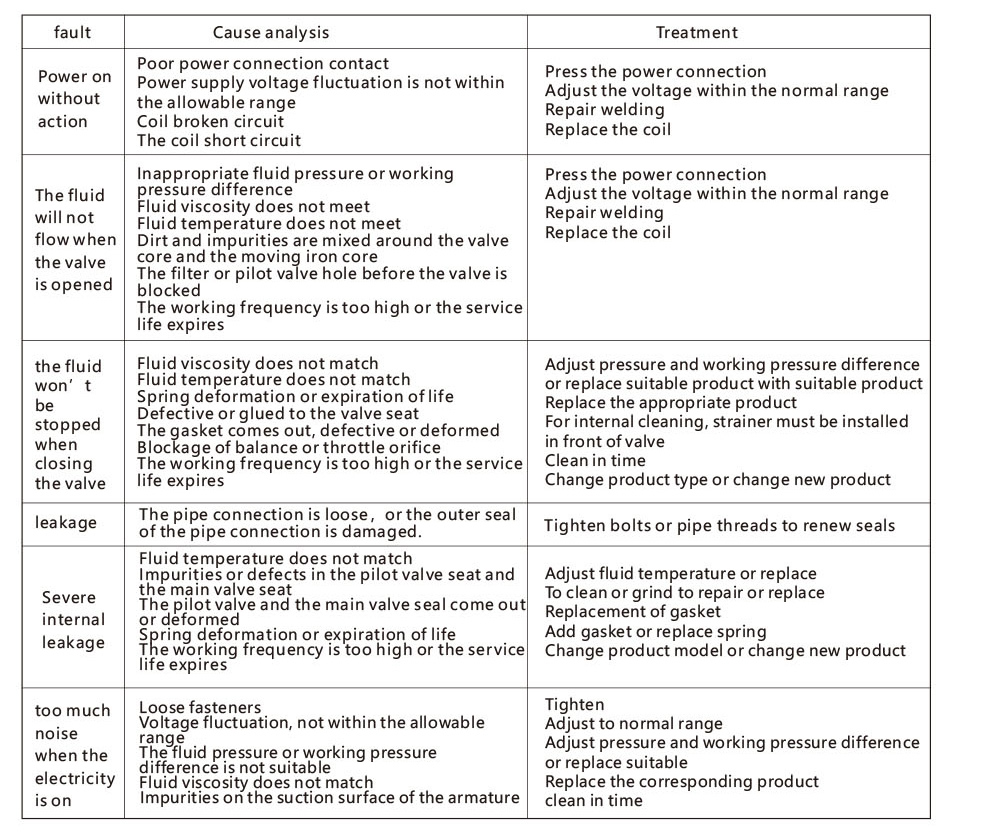

7.Solenoidvalve connection mode is as shown in figure 3

8.Before and afterthe solenoid valve pipeline must be installed pressure gauge, in order to observe thepipeline pressure.

9.In the case of failure of the solenoid valve. in order to timelv isolate the solenoid valve and ensure thenormaloperation, itis best to install the bypass device, as figure l.when the solenoid valve installedinthe branch, solenoid valve diameter should be smallerthan the valve diameter ofthe main pipeline, asfigure 2.

10.The solenoid valve inlet pressure must be greaterthan the outlet pressure, on the contrary, the solenoidvalve willappear normally open state.

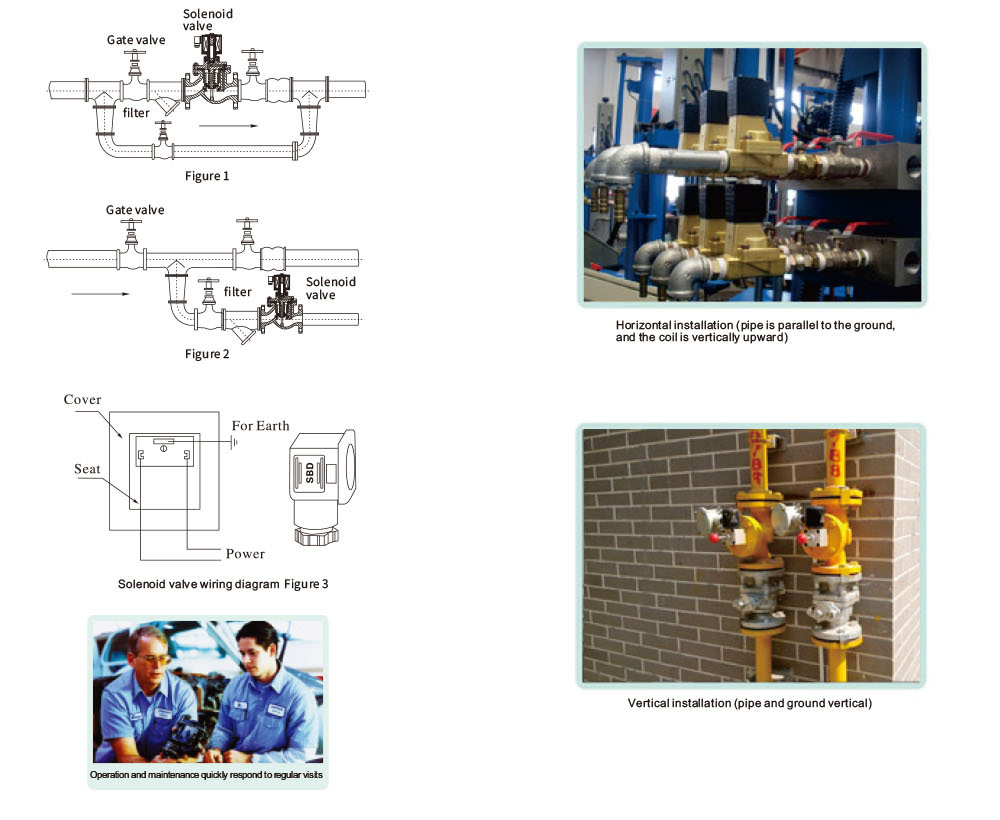

MAINTENANCEANDEXCLUSION

MAINTENANCE AND TROUBLESHOOTING

1. lt is suggested that the user assign a professional person to take charge of operation and maintenance. 2. Annual 1-2 vears of reaular maintenance usina is solenoid valve reliable work and lonaevity ofthe best methodSolenoid valve inside the following four cases, is to prevent the normal operation of the solenoid valve andshorten the life ofthe reason.

(1)Change of medium

(2) Rustin the pipe

(3) air compressor oil oxidation produced carbon particles tar and other sundry mixed into the pipeline

(4)There are dirt and other impurities in the pipeline

3.After the solenoid valve installation or long-term stop when put into operation again must pass into the mediumto try to act severaltimes, the normal work can be put into use.

4. When the steam valve is put into operation after being out of service for a long time, it shall exhaust thecondensate and try to operate for several times before it can be put into use after working normally.

5 Power must be cut off and media pressure removed before maintenance.

6.The coilassemblv should not be disassembled.

7. After disassembling and cleaning, all kinds of parts and components should be reassembled in order.8. fyou have any details about the disassembly sequence, wearing parts and other matters, please consult thetechnicalDepartment.